Displaying items by tag: turbo

Fuel injectors, nearly all cars have them, you probably have heard about them, but do you know what they do and how they do it?

If you now have a reason to be looking into fuel injectors, this is probably the article for you to read.

For this article, we will be concentrating on the common EV1 type injector, but all electrical fuel injectors pretty much work in the same way.

What is a fuel injector?

Pretty much as the name suggests, the fuel injector is an electrically controlled device to inject (or rather spray) a fine mist of fuel, usually there is one per cylinder in your engine, and usually they will open once every two revolutions of the engine.

The fuel is obviously needed to mix with the air being sucked into the engine, to then be ignited by the spark plugs. But for this to happen efficiently, the fuel needs to be sprayed in a fine mist, rather than just a squirt like you would get from a water pistol.

Usually fuel injectors are mounted in the intake manifold, usually quite close to where the intake manifold meets the cylinder head.

How do they work?

Fuel is pumped from the fuel tank at high pressure, usually around 2.5 to 4.0 bar of fuel pressure (or 36 to 58 Pounds per square inch, or PSI), through a fuel filter, and then on to the fuel rail or rails, which often mount to the tops of the fuel injectors and distribute high pressure fuel to all the fuel injectors at the same time.

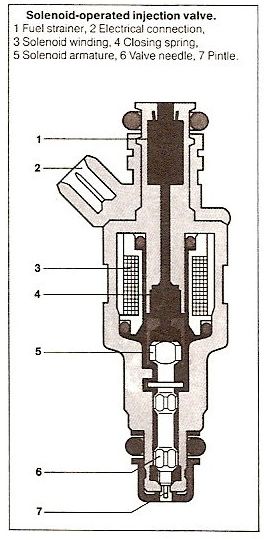

Inside the fuel injectors, there is a coil and armature (or needle valve), which act like a tap to open and close the fuel injectors whenever electricity is passed through the injector. This happens through an electromagnetic effect of the electricity passing through the coil, causes a metal rod through the middle of the injectors, known as an ameture, to move up and down, opening the needle and its seat to allow fuel to flow.

The engine management system (also known as an ECU, EMS or in German cars, the DME), watches the engine via its sensors, and decides when to open and close the injectors, based on how much fuel it thinks the car needs at that precise moment, switching on and off the supply of power flow through the injectors, depending on the car and engine speed, it could be doing this 600 times a second (V8 four stroke engine at 9000 rpm with sequential injection).

At the tip of the injector, which is usually inside the intake manifold, there is usually an opening (or opening) which is designed to shape the fuel flowing out of the injector into a cone shape of finely atomised fuel.

What are the components of a fuel injector.

There are many components within the fuel injector, some of them serviceable as part of a restoration both internally and externally, but some parts are not replaceable.

Coil.

The coil within an injector is effectively copper wire wound around and around in a circle, with a hole through the middle, often this will be wound in a tube shape.

When electricity passes through the coil, it forms a temporary magnet, creating an electro magnetic field.

Usually the coil has an electrical resistance of between 2 and 10 ohms, this is what causes some injectors to be called high or low impedance, another word for electrical resistance. It is important to have fuel injectors of the correct resistance, as the wrong type will either require more electrical energy than your cars wiring or the engine management computer is happy to supply, or will in your car be to weak to accurately open and close completely or fast enough.

Armature.

through the middle of the coil, a rod of good magnetic properties, but be resistant to becoming a permanent magnet, that sits normally at rest, that is until electricity passes through the coil windings.

If you have ever played with magnets as a child, you will know that if you place two magnets together, they will either repel one another with great force, or will be attracted to one another with great force. You may also know that this causes the magnet to have a north and south pole.

When the coil has electricity passing through its windings, in the right direction, it will make a magnetic field with a north or south pole, and therefore will either push the armature upwards, or downwards.

The armature moving upwards, or downwards, depending on the design of fuel injector, will open or close the injector, by lifting or pushing a needle away from its seat which seals the injector.

Armature Spring.

Within the fuel injector, there is also usually a spring, which is designed to return the armature back to its rest position when the coil is no longer pushing the armature using electromagnetic force.

Needle.

Usually, fuel injectors have an internal needle, which moves with the armature, and lifts away from a seat, which allows fuel to flow through a hole in the tip of the injector, also known as the injector nozzle.

Nozzle and cap.

Also known as the pintle protection cap, this is designed to protect the end of the needle and often has a cone shape around the needle to promote the fuel to spray in a cone shape. Usually the cone shape within the protection cap will not actually touch the fuel, but has the effect of shaping the fuel spray pattern.

Internal Filter.

At the other end of the injector, where the fuel enters, is an internal fuel filter, this is the last stage of protection from particles in your fuel blocking the injector or even worse, being abrasive and wearing out the injector.

These filters should not be confused with the main fuel filter, which is usually between the fuel pump (near the fuel tank) and the fuel rail (which supplies the fuel injectors)

Seals.

Normally there is at least two seals on an injector. One sealing the injector into the intake manifold, so that air is not drawn into the manifold around the injector, and another seal at the top to seal the injector into the fuel rail.

Things that can go wrong with a fuel injector.

Blocked filter.

Over time, the fuel injectors internal fuel filter baskets become clogged with debris. This will limit the amount of fuel consumed, and can cause a misfire, which typically will become worse at higher rpm or larger throttle openings. Special tools are required to replace the filter baskets within fuel injectors, and it is important that they are changed with the correct parts with the correct materials. More about this later.

Internal dirt and debris.

As the miles pass by, the fuel injectors can become plugged up with contamination. This can be in the form of a sludge, gum, varnish or even a build up of minerals. Fuel is not perfectly pure, and is after all the processed remains of prehistoric animals and plant life, so it is no surprise that over time small particles get past the filters and slowly build up inside the injectors, limiting fuel flow, but also causing the needle to stick or be slower to move, causing more or less fuel flow than is correct.

Each of these different contaminates have different chemicals which can break them down. To do this the chemical needs to be a solvent (able to dissolve) those contaminates, and the chemical needs to be compatible with fuel (able to be soluble in fuel) but unfortunately, often the contaminants after not soluble in fuel, otherwise they would not have ended up stuck inside the fuel injector, so although fuel additives can help clean some types of contamination from injectors, they rarely will completely clean a fuel injector and sometimes will not work at all.

This is the same problem with the new wave of "on the car" fuel system cleaning machines. Often these machines temporarily replace the fuel pump and fuel tank from the circuit, and can feed the engine with a mix of fuel and harsh chemicals to intensively clean the injectors or carbon from inside the engine. However the problem with these systems, like the fuel additives, is that often the chemicals needed to clean the fuel injectors, are not compatible with fuel. With these machines your injectors and engine are just getting a more intensive cleaning process.

The only real way of cleaning contamination from inside the fuel injectors is to remove them from the car, strip them down completely, and ultrasonically clean the injectors, test them, and then rebuild them with all new consumable parts (filter baskets, seals, spacers, pintle caps etc) But to do this, you need a machine which is able to test the fuel injectors flow and latency (how quickly the injectors open and close), as well as the equipment to strip down the injectors and to fit the new parts properly. You also need one or more ultrasonic cleaners of an industrial grade, as well as some very dangerous chemicals which are extremely hazardous!

At JMG Porsche, we use a Bosch (manufacturer of Porsche injectors) and Lucas (Another injector manufacturer) approved machine for flow testing the fuel injectors. We also use special custom made rig to monitor the fuel injectors to precisely know when they have opened and closed during testing, which means we can analyse if the fuel injectors are taking too long to open and close, which can seriously impact injector performance and the amount of fuel delivered.

We also use a three stage process of cleaning the injectors, in three industrial ultrasonic cleaning machines, which use heated chemicals of different types to clean different types of contamination. This process is so intensive that it even removes paint and corrosion from the fuel injectors, but does not harm good metals or the plastics. (once the injectors are stripped down, cleaned, tested, rebuilt and tested again, we also use a special process to repaint the injectors, so they look like new and are protected from external corrosion.)

Pintle cap wear.

Over time, even though the fuel should not touch them, or barely touches them (apart from with multi orifice injectors), they do wear out over time, can age and crack, causing all kinds of problems with spray patterns. If not caught early enough, the cap can even fall off into the intake of the engine, and be injected by it, causing in some cases catastrophic damage.

Coil failure.

Sometimes the windings within the coils can break. Although this is rare, it can happen. Unfortunately there is very little than can be done with this kind of failure and usually the only way to rectify the problem is with injector replacement.

Needle problems.

In the workshop we have seen injectors fail due to the internal needle breaking or bending. Usually this will be caused either through metal fatigue, or through impact damage. With the second cause, if you have to remove your fuel injectors for any reason, you have to be very careful with how you handle them, they are very delicate. Dropping them, or putting them down nozzle first can damage the tip of the needle.

Sticking armatures or needles.

We are seeing more of this problem now. Usually caused be extreme levels of contamination inside the injectors, but also through corrosion.

In recent years fuel (in the UK and Europe for example) has had an increasing amount of Ethanol (Alcohol) blended with it. This is for environmental reasons and should lower the carbon footprint of your car. However, Ethanol is very good at absorbing water and water vapour, effectively this fuel can suck humidity out of the air! The problem is that the water is obviously corrosive to the internals of the fuel injector.

Ethanol can also attack many forms of plastics and which has meant that for rebuilding fuel injectors, it is important to make sure that the parts are Ethanol Friendly, which many parts sold for Porsche injectors are not Ethanol friendly.

Where to have your fuel injectors repaired?

We never decided we wanted to be in the business of rebuilding fuel injectors. However we had to get involved through necessity!

In years gone by, if a fuel injector failed, it was often possible to buy new ones (Only buy OEM ones, such as Bosch in the case of Porsche injectors) for not much more than the cost of rebuilding them. However Bosch have since 2014 been slowly discontinuing the manufacture of injectors for pre 1998 Porsche models, such as the 944, 924S, 928 and 911 Air cooled models, so over the last few years, we had been actively hunting for a company who could restore fuel injectors back to good working order. This was not as easy as we thought.

As a result, we had to move into the fuel injector restoration business, which was a long three year process of research, training and experimentation. The full story is listed here.

There may be a company near you who can test and restore your fuel injectors, but please use the following check list.

- The repairer has a proper fuel injector flow bench.

- The repairer is able to test the fuel injector latency on opening and closing.

- The repairer is able to test the fuel injector resistance or impedance

- The repairer is using genuine OEM parts to rebuild the injectors.

- The repairer is using proper equipment to strip down and rebuild the injectors.

- The repairer is using a multi stage cleaning process with several different chemicals.

- The repairer is using heated industrial ultrasonic cleaners.

- The repairer will be able to paint the body of the injectors to protect them from corrosion.

- All the parts used must be new fuel/ethanol friendly.

- Most importantly, that they have the specifications for your fuel injectors, for all of the above data to compare to your injectors!

So concludes our initial fuel injector basics article, we hope you have found it useful.

The Porsche security system in the Porsche Boxster 986 models (up to 2004) and the 996 models upto 2005 can be problematic. When faulty they can cause all kinds of strange behaviour, including winding windows up and down, the car not locking or unlocking with the remote or in some cases with the key even, as well as the car failing to start or any combination of these problems.

To help the Porsche community get to the bottom of problems they may be experiencing, we have written this 996/986 Security system 101 article.

Q: Do all Boxster 986 and 996 models have a factory fitted alarm and immobiliser?

A: All 986 and 996 models do have an immobilser, nearly all of them have a combined alarm and immobiliser (I am yet to see one of the rare ones which has the immobiliser only)

For the purposes of this security system primer, we will assume that all the 986 and 996 models are the versions with the combined alarm and immobiliser.

Over the last 20 years since we first started repairing the Boxster and 996 models, we have had to replace hundreds of key remotes and alarm control units, the details of the inner workings of both are an undocumented mystery with Porsche releasing very few details for obvious reasons.

Without having the proper Porsche PST2 (Porsche system tester two) official diagnostic computer, or one of the later PIWIS or PIWIS2 computers, normally only available at Porsche main dealers, or super-duber independents like JMG Porsche, a new alarm control unit or key remote can not be programmed to work with your car.

Even with one of these super amazing factory tools, you also need special numbers, unique to each car, to program the new control units, previously only available from the Porsche main dealer network.

By the time that 2015 rolled around, Jon Mitchell at JMG Porsche was getting a little bit frustrated. Previously every single component within a Porsche car he had intimate knowledge of just how it worked, from the software within the control units, through to the the engines and transmissions, what he did not like was that it seemed that there was a lack of information about the Porsche security systems, even through the official main dealer information systems... So he set about reverse engineering them which has unlocked all of their inner secrets, but for security reasons, only some of them will be ever released to the wider public.. Hopefully though, these details with help other Porsche technicians and Porsche owners understand the security systems in these cars a little better.

So, in essence, without giving too much away.. How does the system work?

There are three main elements to the security system.

- The Key with its key head remote (the black bit on the end of the key with buttons)

- The Key with its transponder (This is buried in the black plastic remote at the end of the key)

- The Key alarm and immobiliser control unit, both housed in a black plastic box, under one of the front seats, waiting for a bath (more on this shortly!)

The key remote head buttons, and the circuit board under them, along with a battery, are there to lock the car (also setting the alarm in the process) and to unlock the car (and unsetting the alarm in the process), apart from on some versions opening the front or rear luggage area, or in others opening the roof. This is all they do (in simple terms)

The transponder chip, completely unattached to the alarm remote other than being housed in the same black plastic blob with buttons, does one thing.. When you put the key in the ignition, a form of magic (known as inductive loop technology) causes the transponder to have a quick chat with the immobiliser side of the alarm control unit, causing the immobiliser to in turn have a chat with the engine management system, and allow the car to start.

The combined alarm and immobiliser control unit, sitting under one of the seats, apart from unlocking and locking doors, immobilising the engine, stopping the windows from working, allowing the windows to wind up and down, and in some models controlling what the roof is allowed to do, also has one other mission in life, detect water, and once detected, panic, act confused or even keel over and die.

Now to learn a bit more about what makes the alarm control unit to fail, before we move onto the remote controls and their problems.

Under the left hand seat (in a right hand drive UK spec car) sits the alarm control unit, which also houses the nerve centre of the immobiliser.. It sits in a slight depression of the metal floor of the car, which is a bit of a problem, because any water that makes it's way into the car will find that depression and fill it up, damaging the alarm control unit in the process.

Traditionally, the alarm system at this point, will be kaput.. It may still work a bit, it may be doing some strange things such as partially working, intermittently working or the car might just be acting possessed. The alarm might start going off for no apparent reason, the windows might start rolling up or down without you ever pressing the buttons, you might even come back to your car and find it locked, even though you were sure you had locked it, or the remote controls might stop working.

In the past, a kaput alarm would have had one cure... Drying out the water (if it had not done it anyway), solving the leak (often on Boxsters the roof drains) and replacing the alarm control unit and the key remotes, sometimes this could cost anything from £1500 upwards in parts and labour!

Following reverse engineering the security systems, we can in many cases repair the alarm control units (and the leak) and have you one your way again, without having to buy a new alarm control unit, key remotes and paying for programming, we can even do this remotely by post or courier.

Another solution, but one which is very much not recommended, would be to buy a used alarm control unit, keys and engine management control unit from a breaker.. However, this is a very big false economy, as you will no longer be able to unlock the immobiliser or engine management control unit to program a future alarm remote, which is inevitable, without then needing to buy a new alarm control unit, key remote and engine management system, or buying another set from a breaker and throwing the previous ones away. Not only this, but a Porsche specialist or main dealer will no longer be able to perform some specialist tasks to your systems, such as programming them with new software which is released on a regular basis (Such as for running the new fuels with higher ethanol content, as is happening right now!)

What kills the alarm control units?

Water usually. In particular with Boxster models you can almost garauntee that whenever it rains, we start to get calls from Boxster and 996 owners with either misfires, cars that will not start or car's which are behaving unusually.

Typically with Boxsters, 996 models with sun roofs or targa roofs, blocked drains or poor seals cause water to run often un-noticed under or behind the carpet and end up filling the small wells or depressions in the floor where the alarm control unit lives. Either killing it completely, or even just making it do unusual things such as the alarm going off intermittently, the windows doing odd things, the car not starting (either failing to run, or the starter motor not working) among many other failure modes.

In the rain when we get calls about a 996 or Boxster (or other models) misfiring, it is usually down to cracked coil packs.

Next, the remote controls can play up in a number of ways...

If you find your Boxster or 996 alarm has stopped remotely unlocking and locking the car via the buttons on the remote control, there could be a number of problems causing this apart from a bad alarm control unit.

The Remote Battery.

In the alarm key remote is a small battery, often, replacing the battery will solve problems with the buttons not locking or unlocking the car, try this first. If you have not replaced your batteries in a year or two, they probably need doing anyway!

The Remote control's computer chip has frozen or crashed.

A few years ago Porsche were so swamped with warranty replacements of the key remotes that they issues a technicial service bulletin (TSB) explaining how to reset a remote control which had crashed or frozen, the process is simple..

- Remove the battery from the key remote

- Insert the battery the wrong way round, flip it, so the writing is facing the other way. Do not worry, this will not damage the remote.

- Press the unlock button continuously while jumping on one foot for sixty seconds (Jumping on one foot is optional but helps pass the time and helps with fitness)

- Flip the battery back around the right way.

- Try the remote control again, if this works you can be sure that the remote had crashed/frozen and you successfully reset it.

The Remote control has become out of sync with the alarm control unit.

Through reverse engineering the software inside the alarm control unit, we were able to de-cypher how the alarm control unit and the key remote talked and how the rolling codes worked.

Rolling codes are not top secret information, they are used in just about every alarm system remote control in the world, both in systems designed by car manufacturers as well as with after-market car alarm system manufacturers. In essence, every time you use the remote control to lock or unlock the car, the alarm system and remote control have a little chat and do not disclose all the details of a very special long number that they both have stored, they just ask one-another mathematical questions about part or parts of the number, and if both of them feel happy about the conversation, they then agree to lock or unlock the car.. Once they have done this, they both take their number and encrypt it slightly to change it for next time, but without ever again disclosing to the other what the new number is.. It should always match as they will have mashed up the number is a very specific way. However, sometimes problems occur.

Potential causes of the alarm system and remote control going out of sync are numerous, they can include the weather, radio interference (such as even a taxi driving past with the driver using a two way radio) or even you being just on the cusp of being close enough or too far away from the car when you used the remote.

In rare cases like this, the key remote or the alarm system may have mashed up it's code to a new version, without the other also doing the same. This is in effect what causes the remote and alarm going out of sync.

Anyway, as we mentioned, at JMG Porsche we reverse engineered the alarm system hardware and software, so discovered a little known and undocumented process to re-sync the alarm control unit and the key remote.. There is a proviso, if the two have gone out of sync by too many steps, the damage has been done and the two will never be able to be sync'ed up again, even with our amazing abilities at JMG Porsche.

The process to re-sync the remote key head is as follows.

- Put the key manually into the door lock (it does not matter if it is already locked or unlocked.

- Press the lock/unlock button and hold it in.

- Turn the key to the lock position and back to the middle position five times and return to the middle position one last time.

- Let go of the lock/unlock button.

- Press and hold in the lock/unlock button again.

- Turn the key to the unlock position and back the middle position five times and return the the middle position again.

- Let go of the lock/unlock button.

- Press the lock/unlock button in again and hold it in.

- Turn the key to the lock position and back to the middle position five times and return to the middle position again.

- Take the key out of the door lock and try the buttons.

If the buttons now work, you have successfully re-synced your alarm system control unit and keys! Well done, go and pat yourself on the back and drink a well deserved beer/coffee/tea/vodka (delete as appropriate) while you reflect on how the key remote might have gone out of sync... Are you a persistent key in pocket fiddler? or did you let your young son or daughter play with your keys? If so, stop it! Or at least now you know how to fix it if it happens again.

However, this will only work if the key remote and the alarm control unit have only stepped a couple of steps out of sync with the alarm control unit, if you are a supper "key in pocket fiddler" or your child has played with the buttons to such an extent that the codes have rolled more than a couple of times, then the key may now be so far out of sync, nothing will bring it back.

Faulty Remote Controls

They are pretty robust units really, but even a Porsche key head remote controls can eventually fail, here are some failure modes.

- Main circuit board failure - This could be as simple as a "dry joint" needing re-soldering, or a crack in the board which may or may not be repairable.

- Button failure - Usually the buttons fall apart because the plastic outer casings button area cracks, causing the button inside to move slightly sideways, rather than just in and out. These can be repaired with a new or used button soldered into the old ones location, and new upper outer shells are available to fix the actual cause.

- Water damage - The remote control key heads have a rubber seal, if when you change the battery this is not re-fitted or if it breaks with age, damp gets in and can destroy the remote. Usually you will see water damage on the circuit board.

- Designed in planned obsolescence - This I feel is a little bit naughty of the designers, or a very simple honest mistake in design. Once the code in the remote has rolled a pre set number of times, after literally hundreds of button presses, it will not be able to roll any more due to how the software was programmed. The alarm system however will continue to roll the code into infinity, so eventually they will go one step out of sync and the love affair between your remote key head and the alarm control system will be over forever.

What can JMG Porsche do to help?

Apart from writing this article so that owners, enthusiasts and even Porsche technicians can understand the system a little better, we have a few things that we can do in house to solve your alarm system problems.

What we and the Porsche main dealers can do, as well as probably a few specialists.

- Programming a new alarm key head remote to your existing alarm control unit.

- Programming a new alarm control unit along with new key head remote controls.

- Diagnosing a problem with the alarm control unit or key remotes.

What we can do that the main dealers can not do and potentially no one else in the world can do in some cases!

- Repairing and refurbishing your current key head remote

- Repairing and refurbishing your current alarm control unit

- Programming a new alarm control unit with your old key remote keys that worked with the old one

- Re-programming a used second hand alarm control unit to work with your car and your key remotes

- Re-programming an incorrectly programmed control unit to be a new virgin unit again, or with the correct data (Useful for other Porsche technicians who have hit the wrong button or experienced power failure during programming)

- Extracting and decoding the unique to your car's Porsche security data needed to program a new control unit, from an old dead control unit

- Extracting and decoding the unique to your car's Porsche security data when Porsche do not have it available (such as with the RUF manufactured Porsche models where Porsche do not have the right data)

- Programming a new alarm control unit on the bench, without ever seeing your car in person, we just need your old alarm control unit, keys and ideally your DME (Engine management computer) Which is useful for those who want to save the labour costs of a Porsche technician to remove the old control unit and fit a new one.

What we can not do..

- Program any random key head remote to your car, it needs to have been previously working with the old control unit at time of failure

What we will not do, even if we can!

- Send you out a new alarm control unit and key remote for a car with just the chassis number unless you provide adequate proof of ownership (A legal authority document such as a log book/V5 (UK) title deed (USA) and a the address of this document has to match the postal address we will send it to.

- Educate or pass on what we have learned from reverse engineering the security systems to any third party other than the information on this page. A software engineer knows the decryption routines but does not know what they are for, an electronics engineer knows the methods to extract the required scrambled data but again does not know what the circuit boards do, and only Jon at JMG knows the full process and processes the repairs. Anyone trying to approach Jon asking or probing for more information will result in the Police being informed. No documents, printed or in data form exist to help anyone else crack the system, so unfortunately the exact process will die with Jon.

What can be done to protect a 986 or 996 from the alarm control unit getting water damaged in the first place?

- Good idea - Getting JMG Porsche to install their 9x6 alarm system drainage port modification to your floor, they let the water out, but do not let it in!

- Good idea - Getting JMG Porsche to install their 986 improved roof drainage system to your Boxster

- Good idea - Routinely check your roof drains for leaves and general debris which accumulate there and remove and clean them, or ask your specialist to do this a couple of times a year for you. It only takes half an hour to an hour in labour and can save you a fortune!

- Bad idea - Fitting a sealed box or bag around the alarm control unit, these rarely are 100% water tight and will often allow water in, but not let it out, so you end up with small amounts of water accumulating over time in the sealed enclosure, but with not enough ventilation for it to evaporate away, until eventually there is enough water to damage the control unit, which can happen in cases where the amount of moisture would not have been enough to cause damage on its own.

And what to never do?

Never, every buy a "set" or "kit" containing an alarm system control unit, DME (engine management computer) and key remotes from a Porsche salvage business and fit them to your car.

- The software in the DME may not be right for your engine, causing all kinds of unseen problems.

- The identity of your Porsche will not match the Porsche database IPAS Codes, meaning that you will NOT be able to program new keys without having to buy a new alarm control unit, DME and key remotes, at a massive cost. Which with a used key remote, is very likely to happen at some point, potentially very soon!

- You will not be able to have your DME reprogrammed over time, such as the roll out of high ethanol fuels which is happening now..

- Your Porsche identity in your control units will not match your car's actual chassis number, you may encounter insurance problems or even end up in hot water with the Police and have to prove the identity of your Porsche is that of the chassis number, such as via a VIC check, which your Porsche will fail due to chassis number mismatches in the various control units versus the number plates worn and the chassis number stamped into the shell. (There have been a number of Porsche that have ended up on Q plates and a dodgy HPI history due to this kind of problem!

A last amusing fact.

Someone at Porsche decided after the 996 and 986 models that perhaps putting the alarm control unit in a depression in the floor, likely to fill up with water was an especially bad idea, so in the 987 Boxster and Cayman models, as well as the 997 models, they moved it away from the floor level and renamed the system as the Porsche Access System (PAS)..

This was a great idea..

Until someone else at Porsche, potentially looking for a good place to put the new "Rear Body Control Unit" (that was a new feature of these cars), had a eureka moment and decided to put this control unit in this really useful empty place under the seat... So if you own a Porsche 987 Boxster, Cayman or 997 and are wondering why your rear lights are doing odd things (brake lights on all the time, reverse lamps on even when not in reverse) or the roof has an interest in suddenly moving up or down, even if locked in position, snapping control rods in the process, then your rear body control unit has probably flooded in exactly the same way that the old alarm control units used to on the earlier model... That is progress for you!

This is not going to be an article about how to change your cam and balance belt on a Porsche 944 or 968, this subject has been covered elsewhere on the internet and personally, it is one of those jobs where if you have not been trained to do it, are not experienced in doing it, you should not do it.. An apprentice at JMG Porsche is not allowed to change a 944/968 cam or balance belt until they have their basic first two years of training under their belt, after that they are supervised on the first few and on probation for the first 4 years with them being checked... So in short, get a pro to do it, ideally a specialist with in depth knowledge of the 944 and 968 engines.

Over the years I have often been asked how often they should change their cam and balance belt on their 924S, 944 or 968, and my answer is "Every 4 years" and change the water pump, front engine oil seals, belt tensioners and rollers every 8 years!

The following questions and answers are here to explain why I advise what I advise and is actually a cut and paste from a recent answer by myself as a technical advisor to the Porsche Club of Great Britain, as a response to a question on their forum.

To an extent, the same advice applies to any belt, on any car, so a Boxster, Cayman or Cayenne/Macan/Panamera or 911 (996, 997, 981 or even air cooled cars) which as a whole do not have cam belts, but do have auxiliary drive belts which if they fail will at best leave you stranded, but at worst can damage the engine or even the bodywork of the car (belts at high speeds make a mess!)

Other than not having a balance belt, the Porsche 928 advice would be the same advice as for the 924S, 944 and 968 owners.

What destroys a belt?

From education training and experience

* Entropy (Everything wants to return to its original component materials) - Very slow

* Oxygen (Oxidises the rubber from the outside inwards, forming cracks eventually, which then allow more oxygen deeper into the belt)

* Wear (Accelerated if the tension is too high or too low)

* Incorrect installation

Who makes the belts for Porsche?

Over the years I have seen the following belts in Genuine Porsche boxes.

* Dayco

* Gates

* Bosch

* Continental

How long can an incorrectly setup or installed belt last?

* As little as a few seconds

* As long as a correctly installed belt

Depends on how incorrectly it has been installed or setup (I have seen many weird things going on in 944 belt covers)

What else accelerates belt degradation?

* Contamination from oil

* Contamination from power steering fluid

* Contamination from coolant

* Contamination from dirt/grit

* Contamination from fuel

* Contamination from plastic dressings

* Contamination from sprays such as WD40

* Ionisation of the air in the cam belt cover

How soon can a correctly tensioned good quality belt without contamination last?

* Soonest I have seen is 5 years with a missing ionisation cap.

* Soonest I have seen with no visible signs of cause - 6 years

* Oldest belt that I have seen break was 26 years old!!!

When would I change the belts on my own 944 fleet?

* Every 5 years without fail and I check inside the cover every year for contamination or issues and always check for leaks every time I drive them.

When would I recommend customers change them?

* Every 4 years (as you might not have your belt, oil seals and leaks checked so often as I do)

How much damage is caused by not changing them?

* Wrecked cylinder head (Valve contacts and bent/detaching valve heads)

* Wrecked pistons (Valve contact, sometimes with valve heads detaching and bouncing around!)

* Wrecked cylinder block (mushroomed out pistons split the bore)

Other advice.

* Change the water pump, tensioners, rollers and front engine oil seals on every second belt change. The water pump can fail through age as well as mileage, as can the seals and tensioners/rollers. Any of these parts can cause the belt to fail.

* Make sure your car has an ionisation cap between the distributor cap and upper front cam belt cover.

This is an important one.

When the 944 was designed, it had a hose that ran between the cam belt cover and air box.. This was to bring fresh air through the belt covers, and remove air which had been ionised by the electrical activity within the distributor cap. There was also a plastic cap between the distributor cap and the cam belt cover, to reduce the amount of contamination of the air within the belt cover with air ionised within the distributor cap.

In about 1988, Porsche eventually go to the bottom of why so many 944s suffered with hydrolocked engines following driving through deep puddles or crossing a river/ford crossing... It turned out that as soon as water was sprayed around the front crank pulley, or the pulley entered water, the water would go into the belt cover and the balance belt would throw this water directly at the vent port which had the hose to the air box.. Once the air box contained a certain amount of water, or you turned a corner, the water would flow through the airflow meter, and get sucked into the engine... Nasty.

Porsche then issued a TSB to say that all Porsche models should have this hose where fitted (important) and a blanking plug fitted (Not so important, I leave them open for ventilation on the advice of my mentor at Porsche).

The problem with this deleted hose, is that without it, it is even more critical to have the ionisation cap installed. They are cheap and available.

That is all :)

Before you set off on a journey of tuning the 944 Turbo, you need to understand the limitations of the 944 Turbo components. Some components hold back performance, others may break before a certain performance level has been reached. Knowing this information is key to being able to get the best from your 944 Turbo.

Just to recap, in part one we covered the various engines installed into the 944 Turbo over its many years of production, if you have not read it yet, stop cheating and read it first before reading this article!

You may have heard this before, but to improve the performance of an engine you need to improve its breathing. Improving the breathing of an engine involves making the engine more efficient at how it breaths in air and fuel as well as its efficiency at expelling the burt fuel and air. This can be done in many ways, including removing restrictions from the breathing (in or out) as well as improving the way the air is processed and presented to the engine.

Lets look at some basic areas of the car and how they restrict performance.

The boost signal line to the wastegate (limits to 250 bhp)

The signal pipe and cycling valve, which sends boost pressure to the wastegate to open it, as standard is designed to limit boost to factory levels. With a standard wastegate it can be improved with a boost profiler, but with a dual port wastegate it would need to be replaced with a manual or electronic boost controller.

Engine management chip (limits to 265 bhp and 260 ft-lbs torque)

The standard engine management chip limits power because that is all it was designed to do, provide software and maps for the standard engine to be provided with the correct fuel levels and spark timing required by a standard engine and turbo. The result is that the engine is limited to 265 bhp, which can be performed by using a boost profiler to allow the engine to hold onto boost a little longer and allow it to build a little quicker. A good upgrade, but don't go any further than this without a replacement performance chip or a custom programmed chip.

The catalytic converter (Limits to 275 bhp and 300 ft-lbs torque)

When fitted, the catalytic converter is designed to change the state of exhaust gases from harmful gasses into less harmful gasses and water vapour. However its design hampers performance and strangles the engine. At best, with the catalytic converter installed, I do not recommend the performance is increased beyond 275 bhp or 300 ft-lbs of torque, as it is not only not nice to the catalytic converter (which can melt, causing a blockage and breakdown) but also to your engine, which will see very high combustion temperatures in the engine as well as in the exhaust. With this limiting item installed, you are limited to a boost profiler device or a set of chips at modest boost levels only. Its replacement can be a "Cat bypass" or "Cat delete" section of exhaust, or its replacement with a silencer.

Fuel pressure regulator (Limits to 275 bhp and 350 ft-lbs torque, with standard injectors)

With standard fuel injectors and fuel pressure regulator, the 944 turbo is limited due to the amount of fuel that can flow through the standard injectors at the standard fuel pressure. Upgrading the fuel pressure regulator to a 3.0 bar item (standard is 2.5 bar) can increase the fuel flow of the standard injectors to around 320 bhp and 350 ft-lbs of torque with the correct engine management chip.

The wastegate (Limits to 300 bhp and 300 ft-lbs torque)

The standard 944 turbo wastegate has a couple of issues. One, it opens slowly as boost increases above atmospheric pressure, this means that as soon as you get any boost, the turbo will begin to see less exhaust gasses flowing into it, therefore causing it to not increase boost as quickly as it could. The next issue is that as the RPM's increase on full throttle and full boost, the exhaust pressure in the exhaust before the turbo will rise to such a point that it will be opening the wastegate early, causing a drop off in boost pressure, which therefore also limits power. This can be improved with fitting a boost profiler, but ultimately a dual port wastegate of good design is required to take the car beyond 300 bhp.

Fuel pump (Limits to 320 bhp and 375 ft-lbs torque, when new!)

The standard Porsche 944 Turbo fuel pump delivers more than enough fuel for a standard engine. In fact a new fuel pump will provide enough fuel for 320 bhp. However, as the fuel pump ages, the fuel flow of the pump reduces, so also the amount of horsepower the fuel pump can provide for also reduces. This is particularly dangerous as if the rest of your package can provide more airflow for power, and your fuel pump is under performing, a lean fuel mixture can cause catestrophic detonation of your engine. Not advised. We recommend the install of a motorsport fuel pump, which fill fit in exactly the same way and provide enough fuel for a 550 bhp monster!

Fuel inectors (Limits to 320 bhp with uprated fuel pressure regulator)

At the standard fuel pressure of 2.5 bar, the standard fuel injectors can only flow around 275 bhp worth of fuel, at 3.0 bar with an uprated fuel pressure regulator they are limited to 320 bhp. Upgrading to larger fuel injectors, such as #55's or #72's increases the fuel flow, which then advances the limits of the injectors drastically.

The air filter box (Limits to 320 bhp and 375 ft-lbs torque)

As standard, the 944 Turbo air filter box and snorkel tube, like many other parts, can only flow a certain volume of air per second. We have found in testing that it usually limits the power to 320 bhp and 375 ft-lbs of torque. Replacement with an induction kit, should remove this limitation.

Typically, many people will tell you that the induction kit needs to place the air filter somewhere that it will recieve cold air, however, when the car is moving, often the under bonnet temperatures where an induction kit will place the air filter will not be as high as one would expect. However a better solution is always to have cool air feeding the air filter.

Replacement of the air filter box with an induction kit will also reduce the amount of time it takes the engine to create boost, making it less laggy.

Turbo Charger - K26.6 (Limits to 290 bhp and 375 ft-lbs torque)

The baby turbo fitted to the 944 turbo from 1985 to 1989 as standard (except Turbo S models) is very good at spooling up quickly and producing boost early, but this very design feature also means it runs out of steam by the time it is flowing enough air to produce 290 bhp. However its ability to spool up quickly means that it can provide quite a lot of torque. Remember, a turbo charger, like an exhaust system limits power due to its ability to move a certain volume of air per second. The lower the engine speed, the more time per second the engine is able to breath, so a small turbo like this can provide a lot of low down power due to its ability to create boost at lower rpms.. But that also means that at higher rpms, the turbo may not be able to keep up, beyond a certain level, the turbo will become inefficient and will generate more heat rather than more airflow beyond a pre set level of load or power. This limit can be removed of course with a bigger turbo, typically though, that also means more lag.

Turbo Charger - K26.8 (Limits to 320 bhp and 365 ft-lb of torque)

This turbo, fitted to the 1988 944 Turbo S and all 944 turbo's after 1989, is able to flow 30 bhp worth of air more, than its little brother the k26.6. Unfortunately it is at the expense of throttle response and increases lag. It was fitted because it allowed the Turbo S and late 944 turbos to produce a higher peak bhp, this often means that a standard 220 turbo is quicker out of the corner (less lag and more torque), but the Turbo S (or 89 on) car is quicker in higher gears. The limitation, like its little brother the K26.6 is due to it moving out of its efficiency band at around 320 bhp worth of air, beyond this it creats heat rather than more power, which can cause detonation of your engine.

Intercooler (Limits to 320 bhp and 375 ft-lb torque)

The standard intercooler design has poor flowing end tanks. There is much debate if this was a designed in feature to stop tuning, or if it was to help distribute flow across the entire intercooler at normal boost and airflow levels. But beyond 320 bhp worth of air, the standard intercooler is unable to flow as much air as the matrix within the intercooler can flow. An intercooler with modified end tanks is required to flow air beyond 320 bhp.

The air flow meter (AFM) also known as a VAF Meter (Volumetric Air Flow Meter). (Limits to 340 bhp and 400 ft-lbs torque)

The standard airflow meter as standard works fine, however it only measures airflow at low and mid range levels of rpm and boost, or to be more accurate "load", as such, when on a full throttle, full boost run, the engine management system is assuming a certain level of boost is being reached at a certain rpm at full throttle, not good for a very high performance car, so it is advised that you upgrade to a MAF sensor before you reach this limit or level. However, it has another limiting factor, which is that it can only flow a certain amount of air, which unfortunately hinders performance gains and limits them to around 340 bhp and 400 ft-lbs of torque. Beyond this, another air measurement device such as a MAF sensor or MAP sensor is required.

The exhaust system (Limits to 350 bhp and 400 ft-lbs torque)

The exhaust system fitted to the 944 turbo typically limits performance to 350 bhp and 400 ft-lbs of torque, this is because the volumes of air (or exhaust gas) required to produce more than this power level are more per second than the standard 944 turbo exhaust system can flow. Try to go beyond this power level with a standard exhaust will result in very little performance gain and increased temperatures within the combustion chamber. The standard system has a diameter of 2.5 inches, where as increasing its diameter, all the way back to the turbo, can remove this restriction. 3 inches is really the sensible upgrade diameter.

The standard engine - M44.50, M44.51 and M44.52 (420 BHP and 420 ft-lbs torque)

The standard 944 turbo engine, no matter what version it is, usually is fine producing 420 bhp and 420 ft-lbs of torque without issues, even if it has many miles on the engine. Obviously, if there is a component within the engine which has not many miles left on its service life, then upgrading the power in the engine is likely to reduce its lifespan. I often tell customers who are interested in tuning their 944 turbo that if their head gasket has not been changed in years and it maybe has another year or two left before it blows, then it may blow much earlier, or even right away if the performance is increased. We have taken standard used 944 turbo 2.5 engines beyond this level of tune, but to be honest, its a worry if the con rods, pistons or other components will survive. Certainly I would say that under 350 bhp a standard engine should have no issues, and ideally if tuning to 420 bhp I would recommend using a M44.50 engine with its superior strong block and pistons, but not essentially.

Conclusion

Every part above can be replaced with a less limited or unlimted item and at JMG we can provide any part you need for tuning your Porsche 944 Turbo, the sky really is the limit, we have even built 3.2 Litre engines for customers which are capable of 700 ft-lbs of torque as well as 2.8 and 3.0 litre turbo engines, every package is different, just as every customer and what they want to achieve is different, so for every package of different parts may provide a different output performance. All of the above information is based on experience and scientific experimentation, however every customer package is dependent on many factors and we can only estimate the final power delivery you may enjoy.

In the next installments we will look at what performance gains can be had from different performance products. But also look out for some of our other technical articles where we will deal with many other aspects of modification and performance tuning.

The different Porsche 944 Turbo engines and the cars they were installed in.

Tuning the Porsche 944 Turbo is something that we at JMG Porsche have been doing extensively for many years. We redesigned the standard 2.5 Litre engine in 2005 to provide the worlds first 3.2 944 Turbo engines as well as building the very best 2.5, 2.8 and 3.0 engines for 944 Turbos. We have even tuned standard engines with over 100,000 miles on the clock to have over 400 horsepower reliably. So you could say we know what we are talking about.

In this series of articles, I plan on showing you what can be done with a 944 Turbo to improve its performance, you will learn what the limits are to the original components and what can be done to improve those components.

So first things first, we need to cover the basic engines installed into the 944 Turbo and the turbo chargers the factory connected to them.

The Engines.

Porsche officially launched three revisions of 944 Turbo engine. The M44.50, the M44.51 and the M44.52.

M44.50

In 1985 when Porsche released the 944 Turbo, the original engine was an M44.50. With a capacity of 2.5 Litres, this engine was designed to be the test bed that the first customers of the 944 Turbo would be unwittingly testing for Porsche along with long term Porsche test cars, some fitted with a M44.50 engine as fitted to the production cars, others fitted with a M44.51 and some fitted with a M44.52. As Porsche were a low volume car manufacturer, this allowed Porsche to trim the production costs of the engines over time, as their test cars mileages rose higher without issues and the customers cars were monitored.

- This original version of the engine, the M44.50 featured the following:-

- Sodium filled exhaust valves

- Ceramic coated exhaust ports

- Modified engine block

- Thicker engine casting with higher density aluminium engine block

- Forged piston connecting rods

- Manual Cam belt tensioner

- K26/6 Turbo (Size 26 compressor matched with a size 6 exhaust turbine.)

This engine produced 220 bhp @ 6000 rpm and 243 ft-lb @ 3500 rpm, and was almost completely bullet proof. If anything Porsche knew it was capable of much higher performance, but due to the superior weight distribution of the 944 design, more performance would have made it faster than the companies flagship 911 Turbo on the road or track. Arguabley the 944 Turbo is faster on the bends and is certainly no slouch on the straights, so it was decided to limit power to 220 bhp.

M44.51

Half way through 1986 the 944 turbo received the M44.51 engine which had now seen another year of testing in the factory road test cars, so it was put into production as the new engine for the 944 turbo. Much the same as the M44.50, but with the following differences.

- Thickness and density of the engine block reduced back to the same as a 944 non turbo to reduce production costs

- Cast piston con rods instead of the expensive forged con rods of the M44.50

For normal or tuning use, there is no difference between the M44.51 and the earlier M44.50 except these components were downgraded in the later 51 engine. However, for the engine builder wanting the best from factory components, a M44.50 block and M44.50 con rods are sought after.

The M44.51 engine still featured the same K26/6 turbocharger and provided the same power output of 220 bhp and 243 ft-lb torque.

M44.52

During 1987, Porsche had finished testing with a new upgrade for the engine, an automatic cam belt tensioner, wider balance shaft belt (most earlier engines were upgraded during service belt replacements) and a deflector rail on the waterpump. Other than this, the engines are identical. This version of the engine continued until the Porsche 944 Turbo stopped production at the end of 1991 and the begining of 1992.

It is said that the M44.52 engine is one that produces 250 bhp, this is not true, but we will cover that in a moment.

The cars.

The early cars before 1987 featured a different wheel offset to the later ones, something that changed with all Porsche models in that year, this was done to improve handling and road safety, although it is also said that these earlier cars are more edgy and track focused, partly due to the lack of option for anti lock brakes (ABS) and a limited slip differential, but also due to the geometry caused by the wheel offset, but thats for another article.

After 1987 the engine changed to the M44.51 engine, performance was unchanged, the wheels changed to the later offset and some extra options became available such as ABS.

In 1988 Porsche had been racing a more powerful and upgraded 944, the 944 Turbo cup for a little while and decided to make a special edition 944 Turbo, the 944 Turbo S. This featured the sports MO30 Suspension and brakes, a larger turbocharger, the K26/8 (Larger exhaust turbine and housing) and a limited slip differential (LSD) all lifted directly from the 944 Turbo Cup race cars. The Turbo S featured 250 bhp @ 6000 rpm and 258 ft-lb of torque, an impressive increase in power, but with slightly more lag than the 220 bhp versions with the smaller turbo. These cars were fitted with the same M44.51 engines that all 944 Turbos had for the previous year and the non turbo S cars of 1988.

The turbo S version of the car was sold as a limited edition, at a price premium. Much to the annoyance of Turbo S owners, the following year in 1989 Porsche upgraded the standard Porsche 944 Turbo so that all 944 Turbo's featured the same K26/8 Turbocharger, and so produced the same power output as a Turbo S. Although in most international markets, the MO30 suspension, brakes and LSD transmissions were still optional.

Over the years there also were many changes to the 944 Turbo other than what we have mentioned here, but we will cover those in other articles as time goes on. For the moment, we have been interested in the engines, the years and what changed, as well as getting rid of some myths at the same time.

By now, you should have a good understanding of the 944 Turbo and its history, as well as the engine and the differences in the engine types.

In the next installment we will look at the Porsche 944 Turbo, component by component, to assess the tuning limitations of each part...

Your Porsche Panamera is in the best of hands at JMG Porsche, where even with servicing we go beyond the factory schedule.

The factory schedule for many models called for a service every two years, which was fine when the car was new and to make the car last beyond the factory warranty without issue. However we strongly recommend that all models are serviced annually, alternating between a minor and a major service each year. Click here and read our article for more information.

Porsche Panamera Servicing and repairs.

Service interval - We strongly advise that all Porsche cars are serviced every year, with a major service every two years.

The service schedule can be confusing with some service items needing to be performed every X amount of years, with other items being specified every Y amount of miles.

At JMG Porsche we have built a database for each model car, where every two years of age for your car, has listed the major service it requires in that year, which combined with every year in between major services the car having an annual service.

This means that for your model of Porsche, we can provide you with a plain price list for servicing, no matter what year your car was made, which makes it easy to see what service items are due and what the total cost will be.

To get a copy of the current service guide and price list for your Porsche, just email us to have your copy emailed to you in PDF format.

Eventually we plan on making it possible to register to the website and be able to download the latest version of this price list - Watch this space!

Your 924, 944 or 968 is in the best of hands at JMG Porsche, where even with servicing we go beyond the factory schedule.

The factory schedule for many models called for a service every two years, which was fine when the car was new and to make the car last beyond the factory warranty without issue. However we strongly recommend that all models are serviced annually, alternating between a minor and a major service each year. Click here and read our article for more information.

Here is a breakdown of our servicing.

Service interval - We strongly advise that all Porsche cars are serviced every year, with a major service every two years.

The service schedule can be confusing with some service items needing to be performed every X amount of years, with other items being specified every Y amount of miles.

At JMG Porsche we have built a database for each model car, where every two years of age for your car, has listed the major service it requires in that year, which combined with every year in between major services the car having an annual service.

This means that for your model of Porsche, we can provide you with a plain price list for servicing, no matter what year your car was made, which makes it easy to see what service items are due and what the total cost will be.

To get a copy of the current service guide and price list for your Porsche, just email us to have your copy emailed to you in PDF format.

Eventually we plan on making it possible to register to the website and be able to download the latest version of this price list - Watch this space!

Interesting service and repair information for the Porsche 924, 944 and 968 models.

Engine failures - Not as common as you would expect, we at JMG Porsche have never had to replace one of these engines due to wear, however we have had to replace many due to insufficient servicing and maintenance, but there are still worthwhile ways of avoiding unexpected large engine rebuild costs. One of which is proper servicing by a real Porsche specialist, which may not need cost as much as you think. There are also some ways to avoid unexpected bills by following some of our other advice bellow.

Brake fluid - Did you realise this should be changed every two years? Not doing this can cause problems with expensive parts within your car, such as the ABS pump or any part of the brake hydraulics due to water contamination as the brake fluid actually sucks moisture out of the air (hydroscopic), so even if the car is not used, the brake fluid must be changed every two years!

Water Pump - Often thought of as a part which fails with age, mileage and quite suddenly, leaving you stranded, our expert technicians are used to inspecting these during services, and so may spot tell tale signs of failure long before they become an issue, so saving you from the indignity of being broken down at the side of the road. A 944 and 968 Waterpump is also part of the cambelt drive mechanism, so it failing can cause serious damage to the cylinder head and engine as a whole.

RMS - Rear main seal - Something else you might see horror stories on the internet about, these used to be a real problem and Porsche re designed the part several times to arrive at the current design which is the only one we at JMG Porsche use. Like an IMS Bearing replacement, this is best performed during a clutch change, however on tiptronic models or on cars not needing a clutch, they can be changed at any time.

Transmission services - Not clearly noted by Porsche for when the transmission should be serviced and this vital expensive part of your car should not be overlooked. Just like your engine, the transmission is filled with oil/transmission fluid, which over time degrades. Not only this, but not many realise that many Porsche transmissions also contain a filter, which becomes clogged over time and can starve your transmission of lubrication, causing expensive repairs. We recommend all Porsche transmissions are serviced every 4 years or 40,000 miles, whichever comes soonest.

Diagnosis - Long has gone where cars had limited electrical equipment and a wiring diagram could be found in a manual from Halfords. Now the Porsche models have multiple separate computer systems, which all talk via networks, and many sensors to feed those computers with information about the world around it all tied together with many hidden wiring looms of thousands of wires and connectors. This can mean that in the event of your Porsche suffering an electrical issue, it is important that a Porsche specialist auto electrician is available, as we have at JMG Porsche. It is also important to understand that sometimes, finding the fault will not be as simple as plugging in a computer.

Drive Belt - Many of you may have had cars where a drive belt, timing belt or cam belt needs to be changed at a regular interval. Your Porsche model has a belt which should be changed every 4 years. Failure to do so can cause instant overheating, loss of power steering and damage to the engine very suddenly. We recommend you have this changed at least every 4 years.

Cam and Balance belt - The 924S, 944 (ALL) and 968 (ALL) have a cam belt and balance belt, which has to be set to a very precise tension and run across various pulleys, tensioners and rollers to function correctly, if these are not maintained with a new cam belt and balance belt every 4 years, and a new waterpump, tensioners and rollers (as well as front engine oil seals) every 8 years, the consequences can be catastrophic to say the least.

Brakes - The Porsche 944S2, 944 Turbo and all 968 models are fitted with Brembo callipers, which overtime suffer from corrosion build up which can cause the pads to stick and bind up within the callipers or even make it difficult to fit new pads. When this happens the calipers require a service rebuild of the slider plate mechanism, which needs to be performed by a specialist with the right experience, techniques and tools to make the repair more than a very temporary one.

Heavy clutch? - A heavy feeling clutch which is stiff to use is not normal on a Porsche and often a sign that the clutch has almost worn out. Ignoring this can cause further damage, such as to the dual mass flywheel and clutch fork.

Alarm system - At JMG Porsche we are experts of all Porsche security systems and have reverse engineered all the various control units. This not only means we can program new alarm control units and keys to your car, just as the main dealer can, but in some cases we can repair your old alarm control unit and keys, or in some cases recover your old keys to be used on the new alarm control unit, which is a service unique to JMG.

Alarm system causes - In most cases the cause of alarm control unit failure is water damage, we can perform modifications to your Porsche model to help mitigate the chances of this happening to your Porsche.

Your air cooled 911 3.2 Carrera, 964 or 993 is in the best of hands at JMG Porsche, where even with servicing we go beyond the factory schedule.

The factory schedule for many models calls for a service every year and in some cases every six months. But with many of these models being infrequently used as they become more valuable, some owners have chosen to service them less frequently. However we strongly recommend that all models are serviced at least annually, alternating between a minor and a major service each year. Click here and read our article for more information. Failing to do this, may not just cause damage to the cars systems, but also may damage its reseal value in a market where service history is king.

Porsche 3.2 Carrera, 964 and 993 Servicing.

Service interval - We strongly advise that all Porsche cars are serviced every year, with a major service every two years.

The service schedule can be confusing with some service items needing to be performed every X amount of years, with other items being specified every Y amount of miles.

At JMG Porsche we have built a database for each model car, where every two years of age for your car, has listed the major service it requires in that year, which combined with every year in between major services the car having an annual service.

This means that for your model of Porsche, we can provide you with a plain price list for servicing, no matter what year your car was made, which makes it easy to see what service items are due and what the total cost will be.

To get a copy of the current service guide and price list for your Porsche, just email us to have your copy emailed to you in PDF format.

Eventually we plan on making it possible to register to the website and be able to download the latest version of this price list - Watch this space!

Interesting service and repair information for the air cooled 911 models.

Engine failures - Not nearly as common as horror stories on the internet of top end rebuilds being required every 130,000 miles would have you believe, but there are still worthwhile ways of avoiding unexpected large engine rebuild costs. One of which is proper servicing by a real Porsche specialist, which may not need cost as much as you think. There are also some ways to avoid unexpected bills by following some of our other advice bellow.

Brake fluid - Did you realise this should be changed every two years? Not doing this can cause problems with expensive parts within your car, such as the ABS pump or any part of the brake hydraulics due to water contamination as the brake fluid actually sucks moisture out of the air (hydroscopic), so even if the car is not used, the brake fluid must be changed every two years!

Transmission services - Not clearly noted by Porsche for when the transmission should be serviced and this vital expensive part of your car should not be overlooked. Just like your engine, the transmission is filled with oil/transmission fluid, which over time degrades. Not only this, but not many realise that many Porsche transmissions also contain a filter, which becomes clogged over time and can starve your transmission of lubrication, causing expensive repairs. We recommend all Porsche transmissions are serviced every 4 years or 40,000 miles, whichever comes soonest.

Diagnosis - Long has gone where cars had limited electrical equipment and a wiring diagram could be found in a manual from Halfords. Now the Porsche models have multiple separate computer systems, which all talk via networks, and many sensors to feed those computers with information about the world around it all tied together with many hidden wiring looms of thousands of wires and connectors. This can mean that in the event of your Porsche suffering an electrical issue, it is important that a Porsche specialist auto electrician is available, as we have at JMG Porsche. It is also important to understand that sometimes, finding the fault will not be as simple as plugging in a computer.

Drive Belt - Many of you may have had cars where a drive belt, timing belt or cam belt needs to be changed at a regular interval. Your Porsche model has a belt or belts which should be changed every 4 years. Failure to do so can cause instant overheating, loss of alternator charging and damage to the engine very suddenly. We recommend you have this changed at least every 4 years.

Heavy clutch? - A heavy feeling clutch which is stiff to use is not normal on a Porsche and often a sign that the clutch has almost worn out. Ignoring this can cause further damage, such as to the flywheel and clutch fork.

Alarm system - At JMG Porsche we are experts of all Porsche security systems and have reverse engineered all the various control units. This not only means we can program new alarm control units and keys to your car (late models), just as the main dealer can, but in some cases we can repair your old alarm control unit and keys, or in some cases recover your old keys to be used on the new alarm control unit, which is a service unique to JMG. For all air cooled 911 models we can bypass the original alarm system and install more modern alarm systems in their place which are Thatchum (insurance standard) approved.

Alarm system causes - In most cases the cause of alarm control unit failure is water damage, we can perform modifications to your Porsche model to help mitigate the chances of this happening to your Porsche.